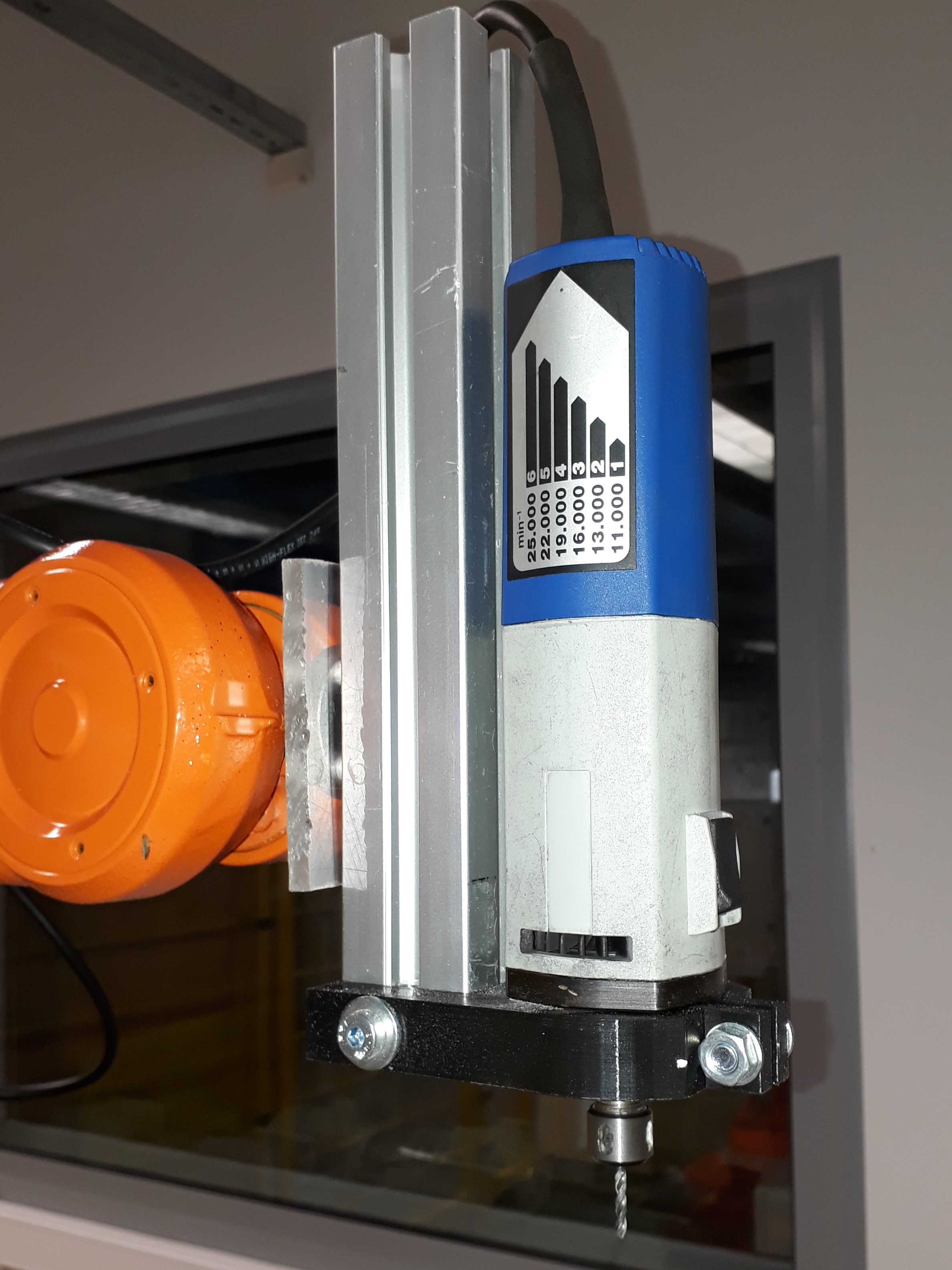

Minifrees (rotary tool) Dremel

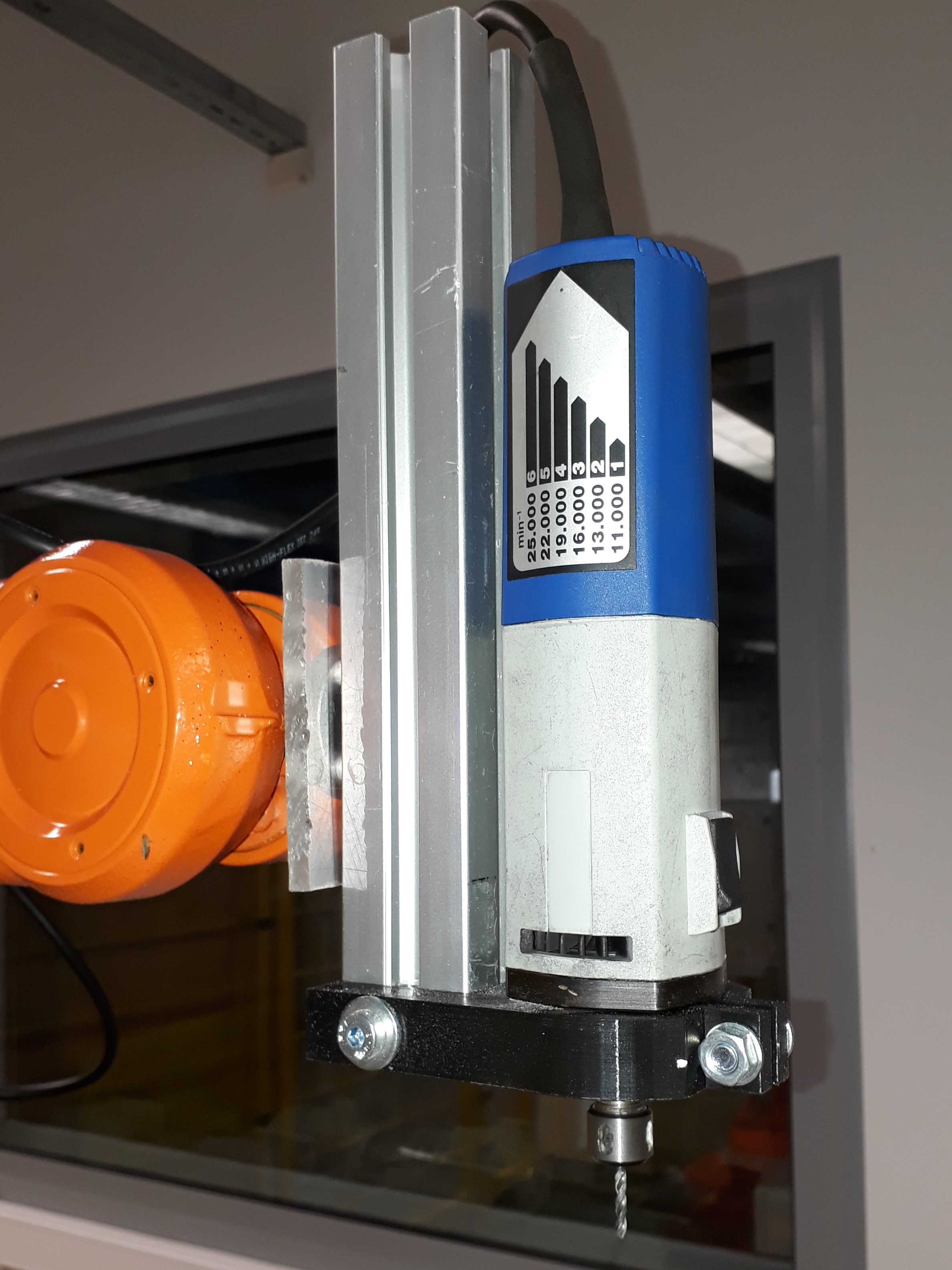

UFM500

| Title | Author, year | Description (The thesis aims to) | Programming languages or data formats uesed | Hardware used | Prototype testing videos |

| System design for palletizing bags (or sacks) onto a pallet | Vladislav Magilnitski, BSc 2024 | The thesis aims to develop a system for Palletizing sacks onto a EPAL3 pallets, to develop a preliminary palletizing algorithm and analyze the system’s technical and economic aspects such as return on investment (ROI), risk assessment and performance evaluation. | ABB RAPID, ABB Robotstudio add-on tool Palletizing PowerPac generated visualization in GLB format | ABB IRB 460 with ABB ClawGripper, EN13698-2 pallets (simulation with in ABB Robotstudio Palletizing PowerPac), some robots from Kuka, Yaskawa and Fanuc in comparison | |

| Machine-Vision-Based Manipulator Positioning System for Sorting | Mulat Tigabu Girmay, MSc 2022 |

The thesis aims to develop a machine vision-guided robotic system for automated sorting tasks. The system integrates a vision sensor such as Cognex camera with a robotic manipulator to detect, locate, and sort objects based on visual features. Cognex camera is applied for object detection and pattern recognition. Extracts object coordinates and orientation from captured images. | ABB RAPID | An ABB YuMi dual-arm robot is used for object handling. it receives position data from the vision system to perform pick-and-place operations. |

|

| Reconstruction and conversion of a manual milling machine to computer numerical control | Hardi Tambets, BSc 2021 |

The thesis aims to convert a manual milling machine into a CNC (Computer Numerical Control) machine, while retaining the option for manual operation. This topic was motivated from the need for a affordable, flexible machining solutions in student-led projects at Tallinn University of Technology’s Robotics Club. Popular CNC controllers (e.g., Centroid Acorn, Mach3) were compared to select the most suitable one. Custom mechanical parts were designed and manufactured for the conversion. Detailed schematics were created to integrate the selected controller with the mechanical and electrical systems of the milling machine. | G-code, CAD/CAM formats | The system was demonstrated using a CNC machine (Optimum BF20L) in TalTech Robotics club. |

|

| Integration of Industrial Manipulators and Mobile Robots with Open-Source Software Platform ROS | Andre Talvoja, BSc 2021 |

The thesis aims to create a unified control system that enables robotic tasks in industrial automation independent of manufacturer specific languages. ROS is used to manage communication between different robotic components. Middleware handles sensor data, actuator commands, and coordination logic. | Python | The system was demonstrated using a Mitsubishi MELFA industrial robot and a mobile robot platform available in TalTech. |

|

| Electromagnetic Near-field Scanner Based on Industrial Robot | Vladimir Šulžik, BSc 2020 |

The thesis aims to design and implement a system that uses an industrial robot to perform electromagnetic near-field (EMNF) scanning. The goal is to automate the scanning process for analyzing electromagnetic emissions from electronic components or systems. The spatial coordinates from the robot were mapped to the measurement data to generate near-field emission maps. | MATLAB was used to process and visualize the collected electromagnetic data, C (Arduino IDE) was used for magnetic sensor interfacing, CSV (comma-separated values) was used to store data | Honeywell magnetic sensor SS496A1, Mitsubishi RV-1A robot with FESTO DGE linear axis | |

| Guides for Working with Industrial Automation 3D Modelling Package | Siim Kallisaar, BSc 2020 |

The thesis aims to create step-by-step beginner guides for using a 3D modeling package (Ciros Studio) in the context of industrial automation. It focuses on helping users model and simulate automation systems that include hardware components and programmable logic controllers (PLCs). |

FBD (Function Block Diagram, CoDeSys), SFC (Sequential Function Chart, CoDeSys), MELFA Basic, KRL (KUKA Robot Language), IRL (DIN 66312) |

Mitsubishi RV-1A robot with FESTO DGE linear axis, Festo MPS Distributing station |

|

If you plan to develop a real physical prototype, you are welcome to my

guidance (and supervision).

Don't forget that you do everything for

yourself, not for me.

| Title | Author, year | Description | Programming languages or data formats uesed | Hardware used | Prototype testing videos |

|

Alternative tools for industrial robot IRB1600: Minifrees (rotary tool) Dremel |

2019 |  |

ABB RAPID (Robotstudio Machining PowerPac, etc.) | IRB1600-1.45 with IRBP positioner, 3D printed tool holder, Dremel rotary tool | |

| Alternative tools for industrial robot IRB1600: UFM500 |

2019 |  |

ABB RAPID (Robotstudio Machining PowerPac, etc.) | IRB1600-1.45 with IRBP positioner, tool holder, UFM500 |